Engines / Diesel / 1.6/77kW TDI-CR CAYC;CLNA / Test of exhaust gases temperature sensor 1; 3 (G235; G495; 648)

Mark

Model

Control unit

Diagnostic operation

Mark

Škoda

VW

Audi

Seat

Cupra

Lamborghini

Porsche

Bentley

MAN

Service intervals

Engines

Gearboxes

Immobilizers

auxiliary heater

Model

UDS Engines by part number

Diesel

Petrol

Control unit

1.4/55 kW 3V TDI PD AMF/BMS/BNM/BNV

1.6/55kW TDI-CR CAYA

1.6/55kW TDI-CR CAYE

1.6/66/77kW TDI-CR CLHx UDS

1.6/66kW TDI-CR CAYB

1.6/75kW TDI-CR CAYD

1.6/77kW TDI-CR CAYC;CLNA

1.9/47 kW SDI ASY

1.9/50kW SDI AGP;AQM EU-3

1.9/66 kW TDI AGR; ALH

1.9/66kW TDI-PD BRU; BXF

1.9/74 kW TDI etc

1.9/74kW TDI BEW;BRM

1.9/74kW TDI-PD AVQ

1.9/74kW TDI-PD BMT

1.9/75/62 kW TDI BRS;BRR

1.9/77 kW TDI PD

1.9/77kW TDI-PD AXB; AXC

1.9/77kW TDI-PD BKC; BJB; BXE

1.9/77kW TDI-PD BLS; BVB; BXJ; BSU

1.9/81kW TDI AHF;ASV EU 3

1.9/85kW TDI-PD BKE;BRB

1.9/96kW TDI

2.0/100 kW TDI-PD BGW

2.0/100/103kW TDI-PD BLB;BNA;BRE;BRF;BVF;BVG

2.0/100/103kW TDI-PD-DPF BRE

2.0/103kW TDI-CR CBAx

2.0/103kW TDI-CR CFFx;CFGx;CFHx;CLCx;CMGB UDS EDC17 C46

2.0/103kW TDI-PD BKD; AZV

2.0/103kW TDI-PD BMM;BMP

2.0/103kW TDI-PD BPW;BRC

2.0/103kW TDI-PPD BKP;BMA;BVE;BWV

2.0/103kW TDI-PPD BRT

2.0/120;125kW TDI-PPD BRD;BVA

2.0/125kW TDI-PD BMN; BMR; BUY; BUZ

2.0/75kW TDI-CR CUUx UDS EDC17C64

2.5/110kW TDI 6V AFB; AKE; AKN; AYM; BAU; BCZ; BDG; BDH; BFC

2.5/110kW TDI AFB; AKN

2.5/114 kW TDI 6V AYM

2.5/120kW TDI 6V BDG

2.5/128 kW TDI-PD BAC

2.5/128/120/96 kW TDI-PD AXE; BLJ AXD

2.5/128/96 kW TDI BPC; BNZ

2.7 TDI CR

3.0 TDI CR

3.0 V6 TDI BKS BMK BUN (3.0L V6TDI)

4.0 TDI CR

4.2 TDI CR

5.0/230 kW TDI-PD AYH

6.0 TDI CR

COMMON PROCEDURES

Continental SIMOS PCR 2.1 Continental CAYx UDS general

EDC 15 general

EDC 16 general

EDC 17 CAN general

EDC 17 UDS general

Diagnostic operation

turbo blower - replacement (adaptation)

Automatic test procedure

creation of Readiness

Cruise control Activation / Deactivation

Security access

injector: corrective value - Test

Adaptation of injection valve after replacement

Test / activation of fuel pump and control relay

Check of clogging level of Diesel particulate filter

Adaptation of the deviation of the minimum number of injectors

Bleeding of fuel system

DPF regeneration

settings - filling pressure controller - turbo blade geometry sensor

Evacuation of fuel tank

reset of DPF clogging

Adaptation of DPF differential pressure sensor

zeroing learning values - Lambda sensor(s)

zeroing learning values - Adaptation of the mean quantity value

zeroing learning values - Quantity measuring unit - regulator valve

Test of load signals for alternator

Test of filling pressure

Test of cruise control

Test of pedal switches

Test of filling and atmospheric pressure sensor

Test of intake air temperature sensor (G42)

Test of engine temperature sensor (G62)

Test of air mass sensor (G70)

Test of fuel temperature sensor (G81)

Test of engine temperature sensor - outlet from radiator (G83)

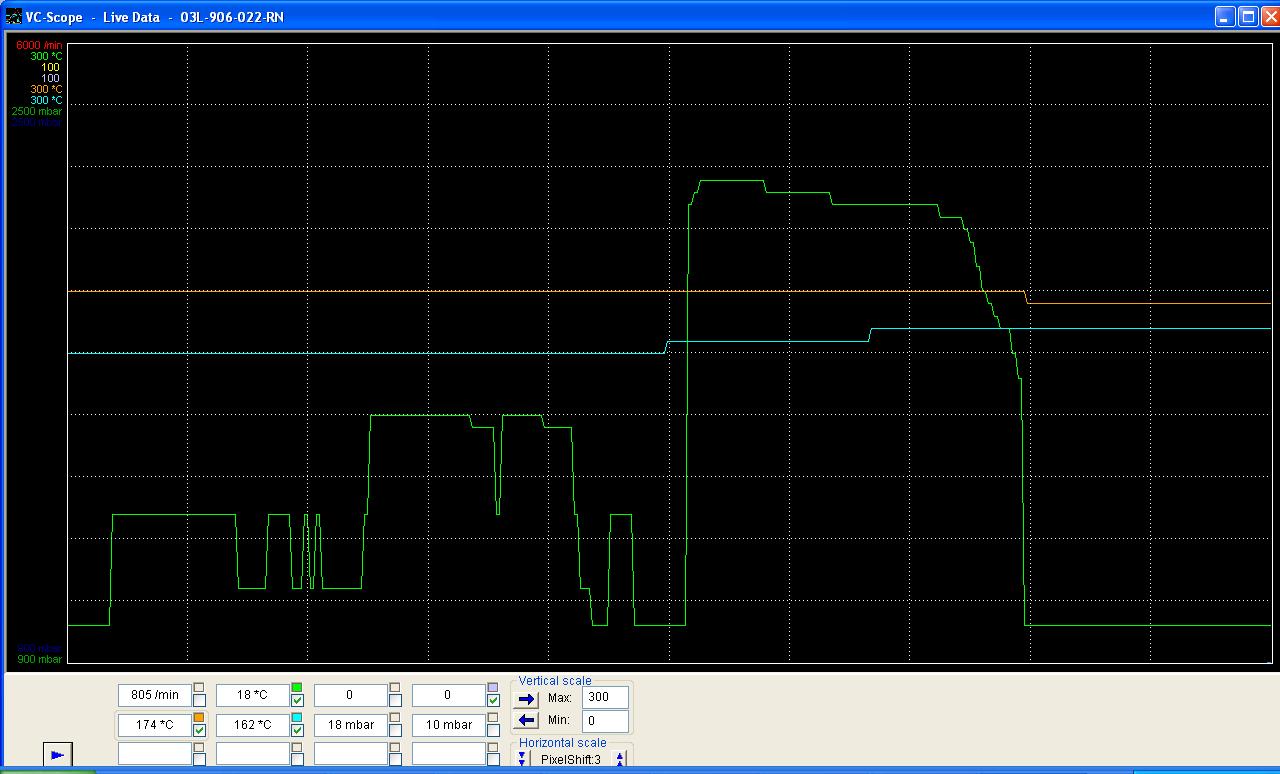

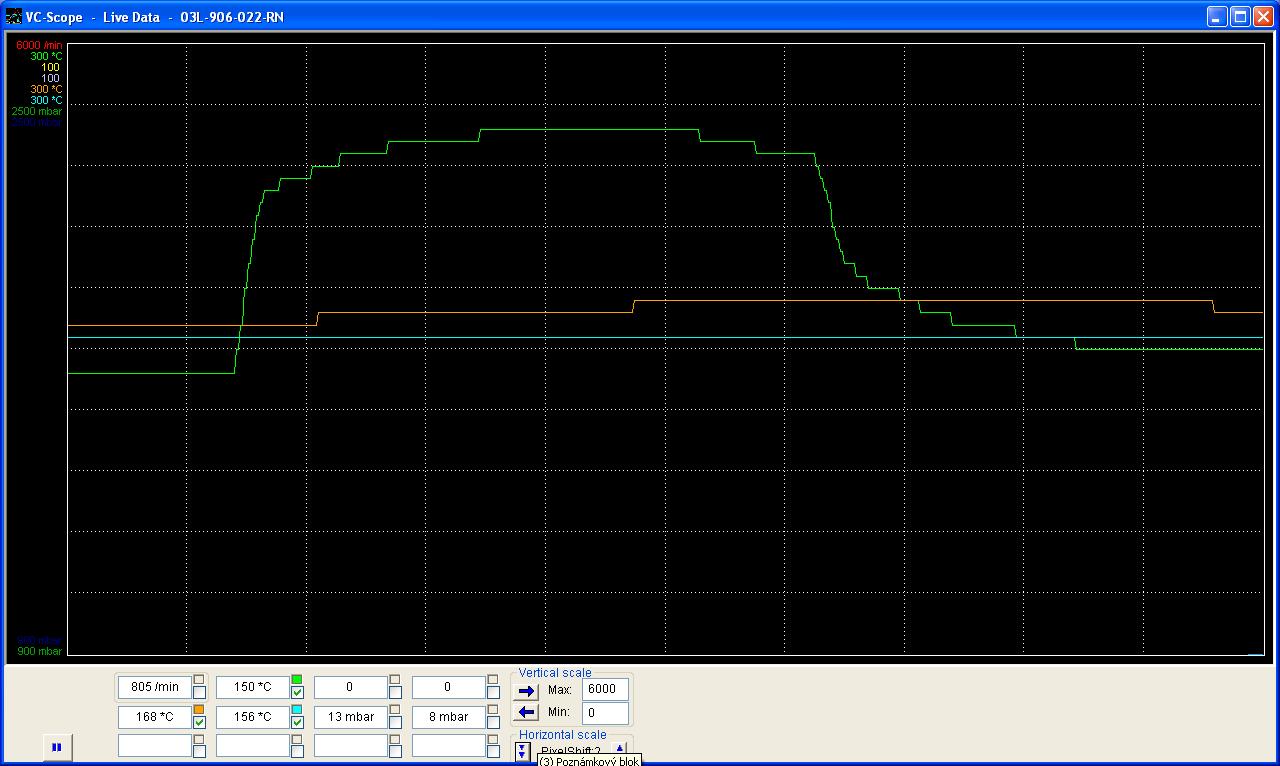

Test of exhaust gases temperature sensor 1; 3 (G235; G495; 648)

Test - fuel pressure - pressure sensor (G247)

Test - fuel pressure - pressure sensor (G247) - general

Test of DPF differential pressure sensor 1 (G450)

Test - filling pressure controller - Position sensor (G581)

activation - fuel pump (G6)

Test of heating (glow) unit (J179)

Test of radiator fan control unit (J293)

Test - small heat capacity relay (J359)

Test - large heat capacity relay (J360)

Test - system indicator light: glowing (K29)

Test - Emissions Indicator Light (K83)

Test - system indicator light: Diesel Particulate Filter (K231)

Test of gas pedal position sensor 1 (G79)

Test of gas pedal position sensor 2 (G185)

Test - throttle valve: control unit (J338)

Test - exhaust gas return valve 1 (GX5)

Test - Change-over valve for the cooler of the exhaust gas recirculation

Test - filling pressure control valve (N75)

Test - fuel pressure regulation vlave (N276)

Test - Fuel metering valve (N290)

Test - Change-over valve for the cooler of the exhaust gas recirculation (N345)

Test - Coolant pump for EGR (V178)

customer limitation of maximum speed

Neutral gear sensor - adaptation

Kick-down - adaptation

Test - idle stabilization

Measurement of compression pressure

Diagnostic procedure

You are not logged! System works in DEMO mode only now where numbers are replaced with X characters. For 49 EUR onl y You will get access into full system. You can pay by credit card or bank transfer. Click BUY button for purchase and You will get login to diagnostic procedures database imediatelly.

Log-in

Buy

Conditions: - engine temperature = XX°C + connect with the control unit XX - engine Start the engineidling Advanced Measured Values select item in menu : IDEXXXXX - ENGXXXXXX - temperature of exhaust gases X-TEG_MES[X] (temperature upstream of component: turbo blower) IDEXXXXX-ENGXXXXXX - temperature of exhaust gases X-TEG_MES[X] (temperature upstream of component: Diesel Particulate Filter) IDEXXXXX-ENGXXXXXX - temperature of exhaust gases X-TEG_MES[X] (temperature downstream of component: Diesel Particulate Filter) TIP! For easier search in the menu, enter the code IDE, ENG or MAS into the "Filter" window increase rpm to XXXX rpm desired condition: X-TEG = increasing - strongly X-TEG , X-TEG = increasing - moderately X-TEG > X-TEG > X-TEG for this test, it is suitable to use graphical representation VagScope

example: if values are not achieved - check component: - temperature sensor - wiring

You are not logged! System works in DEMO mode only now where numbers are replaced with X characters. For 49 EUR onl y You will get access into full system. You can pay by credit card or bank transfer. Click BUY button for purchase and You will get login to diagnostic procedures database imediatelly.

Log-in

Buy

Diagnostic procedures for a VAG diagnostics

Diagnostic procedures for a VAG diagnostics Database for coding vehicle control units Volkswagen - VAG

Database for coding vehicle control units Volkswagen - VAG Software versions

Software versions VIN - Code validator

VIN - Code validator